Concerned about protecting your valuable equipment from theft and misuse? Track tools with GPS! A GPS tracker for equipment provides real-time location tracking to ensure your assets are secure and efficiently managed. In this article, we’ll cover the essential benefits of a GPS tracker, various types suited for different equipment, and practical use cases to enhance your operations.

KEY TAKEAWAYS

- GPS is an abbreviation for Global Positioning System.

- A GPS tracker for tools enhances security for high-value equipment by preventing theft and unauthorized use.

- Different types of GPS tracking cater to specific equipment needs, including heavy construction machinery, vehicles, and portable tools, ensuring durability and continual operation in harsh conditions.

- Key features of GPS tool trackers include real-time location updates, geofencing alerts, historical data analysis, and maintenance reminders, promoting operational efficiency and effective asset management.

- The best GPS equipment trackers are ToolSense Rocbird, Qtanium 400 and TS10.

- ToolSense offers a comprehensive solution that combines asset management, maintenance management, work order management and inventory management with modern IoT tracking devices, such as GPS trackers or Bluetooth sensors.

Equipment Tracking Devices

GPS Trackers

GPS (Global Positioning System) trackers use satellite signals to provide precise, real-time location data for equipment. These trackers are essential for monitoring high-value assets like heavy machinery, vehicles, and portable tools. GPS equipment tracking offers extensive coverage and is effective in both urban and remote areas. GPS technology ensures continuous monitoring and enhances the security and efficiency of equipment management.

Bluetooth Trackers

Bluetooth trackers are small, battery-powered devices that use Bluetooth technology to communicate with nearby smartphones or central gateway devices. These trackers are ideal for short-range tracking and are often used for tools and smaller equipment. They provide real-time equipment location updates within a limited range, making them perfect for indoor environments like warehouses or job sites. The data collected by Bluetooth trackers can be accessed through mobile apps, ensuring easy management and quick location of assets.

RFID Tags

RFID (Radio Frequency Identification) tags are used for tracking and identifying items using radio waves. These tags can be passive (without a power source) or active (with a battery), and they communicate with RFID readers to provide location data. RFID technology is highly effective for inventory management and tracking large volumes of equipment. It allows for quick scanning and identification of multiple items simultaneously, streamlining the asset management process.

QR Tags and Barcodes

QR tags and barcodes are visual codes that can be scanned using your mobile device or dedicated scanners to access information about the tagged item. These tags are cost-effective and easy to implement, making them a popular choice for tracking and managing smaller tools and equipment. By scanning the QR code or barcode, users can quickly retrieve details such as the item’s location, usage history, and maintenance records, ensuring efficient asset management.

Learn more about the different equipment tracking methods in our blog-article.

Why GPS Trackers Are Essential for Equipment Security

A GPS tracker prevents theft and unauthorized use of high-value equipment, ensuring their security. In industries like construction, manufacturing or facility management, where equipment theft can result in significant financial losses, an equipment tracking system offers a robust solution. These devices offer real-time location updates, providing immediate alerts and notifications about equipment whereabouts, crucial for theft prevention.

Custom notifications enable users to monitor their equipment. Detecting unusual behavior immediately enhances security, allowing for swift action to prevent potential theft. Geofencing technology alerts users if equipment leaves designated areas, further improving security measures. This feature ensures prompt detection of unauthorized movement, allowing for immediate alert.

These combined security features aid in the immediate recovery of stolen tools and form a comprehensive strategy for managing valuable equipment effectively. Asset GPS trackers provide constant vigilance over assets, significantly reducing risks.

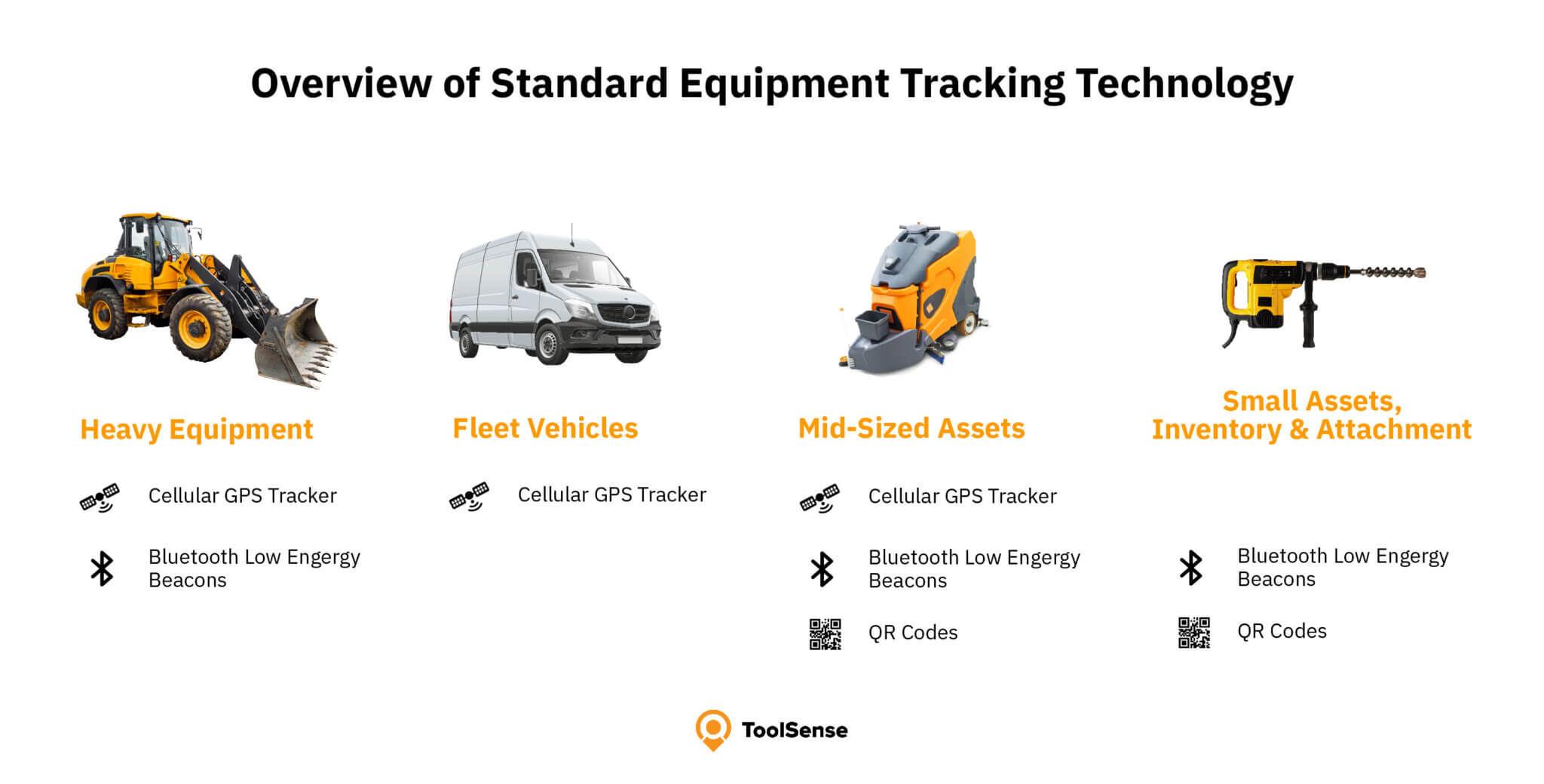

Types of GPS Trackers for Different Equipment

Various GPS trackers cater to specific needs when protecting and managing different types of equipment. For heavy construction machinery like excavators and bulldozers, GPS tracking solutions provide real-time visibility into the location, usage, and status of these assets, enhancing operational efficiency. The durability and accuracy of these trackers, often equipped with shock mode alerts, make them suitable for harsh construction site conditions.

Cars and heavy goods vehicles benefit from OBD GPS trackers and hardwired GPS trackers. OBD GPS track equipment plug into the vehicle’s on-board diagnostics port, drawing power from the electrical system and offering detailed insights into vehicle performance. Hardwired GPS trackers connect directly to the equipment’s electrical system, ensuring continuous monitoring and compliance.

A battery-powered GPS tracker offers a flexible solution for smaller tools and non-powered assets. The equipment tracking can be easily attached without wiring and provide standalone tracking capabilities, ideal for tools and generators. Bluetooth and RFID tracking devices are also used for equipment tracking devices, each suited for specific applications.Durability is crucial for all types of GPS trackers, especially those used in construction. They must withstand harsh environmental conditions to ensure continuous operation. Whether using GPS, Bluetooth, or RFID technology, these systems provide a comprehensive approach to effective equipment management.

How does Tool Tracking via GPS work?

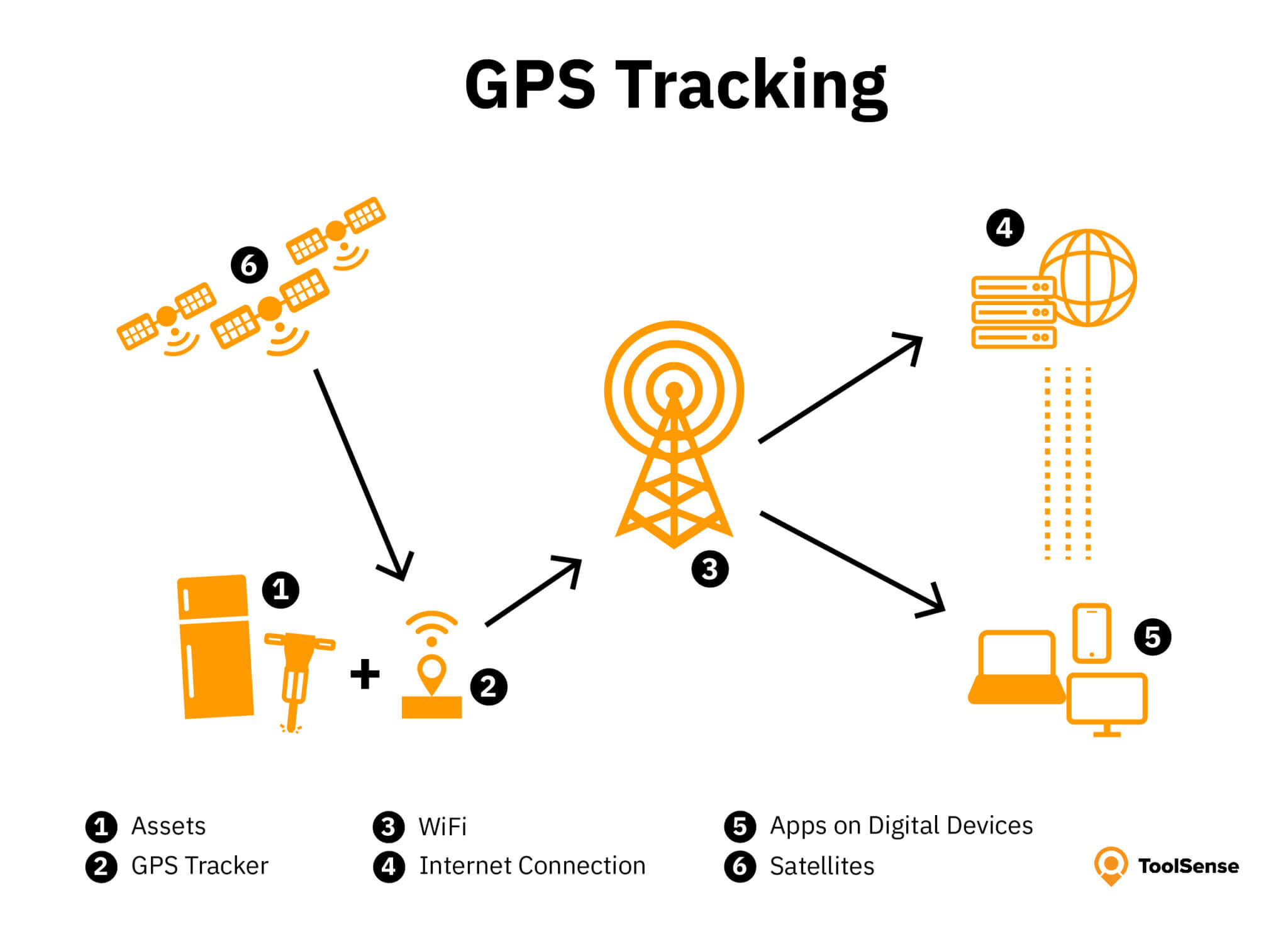

The Global Positioning System is a network of satellites orbiting Earth. These satellites emit signals that GPS trackers on devices like construction equipment or mobile phones can receive.

By processing these signals, GPS devices can pinpoint the exact location of the device anywhere in the world. However, it’s worth noting that GPS signals may struggle to penetrate solid structures like walls, and slight inaccuracies of 5 to 10 meters can occur due to atmospheric conditions.

Features of GPS Tool Trackers

When it comes to construction equipment GPS tracking, it’s important for companies to carefully consider the key features offered by each system before making a commitment. To ensure they choose the best option, businesses should look for the following features in a reliable equipment tracker:

Managing your equipment shouldn’t be hard. That’s why Excel, WhatsApp, or Pen & Paper are not the right tools. No matter the manufacturer or type of your equipment–ToolSense provides the perfect GPS tracking solution for your company.

1. Real-Time Data and Vehicle History

Real-time insights are an indispensable feature and absolutely essential for GPS tracking of construction equipment. Knowing the exact location of your construction equipment is not only vital to prevent loss or theft, but it can also enhance asset utilization. The vehicle’s history contains important tracking information, such as engine hours and locations, which can provide valuable insights into its usage and criticality. This data can help companies devise effective maintenance plans for specific equipment. Considering the importance of such data and its accuracy, it’s prudent to ensure the use of reliable asset tracking software and the appropriate GPS tracker.

2. Customizable Alerts

Companies can leverage equipment tracking software and devices to tailor their alerts, which can be delivered as in-app notifications or email alerts. These alerts notify employees of any runtime issues or problems with heavy equipment that has a GPS tracker attached. Some software also supports the creation of a geofence, an invisible boundary. If a vehicle or piece of equipment exits the specified perimeter, employees will receive a notification, helping to prevent potential asset theft or misuse.

3. Reporting and Analytics

In the modern era, IoT solutions like GPS tracking for construction equipment should include advanced reporting and analytics features. Gathering tracking data is just one aspect; interpreting and presenting this data comprehensively for businesses is equally crucial. This deeper insight into each asset allows companies to pinpoint problem areas, assign appropriate criticality levels, develop more effective maintenance plans, and maximize the utilization of existing equipment.

4. Maintenance Management

Regular maintenance is essential to keep construction equipment operating efficiently. However, determining the frequency of maintenance and assigning the right personnel can be challenging. Additionally, understanding the findings from recent inspections is crucial.Utilizing GPS tracking for heavy equipment allows companies to access more than just location data. They can also collect and analyze machine data to develop a maintenance schedule and organize inspections and repairs within the software.

Managing maintenance is quite a challenge. A maintenance management software helps you to easily manage processes for thousands of assets.

5. Work Order Optimization

Managing work orders can be challenging when employees are dispersed across different construction sites. To streamline this process, construction GPS equipment is commonly paired with software that allows employees to issue and receive work orders from any location at any time. This is particularly important for work orders related to critical maintenance tasks and inspections that on-site workers might otherwise overlook.

GPS Tool Tracker – Track Vehicles and Heavy Equipment

Rugged GPS track equipment endures harsh conditions, capturing location data and detailed engine metrics like hours of operation and fuel consumption. These features are beneficial for tracking heavy machinery and construction equipment, ensuring efficient use and proper maintenance. Hardwired GPS trackers for heavy goods vehicles are essential for compliance, offering advanced analytics on vehicle and driver behavior.

A battery-powered GPS tracking device for non-powered assets provides long-lasting location tracking and can be mounted securely. These trackers are ideal for smaller tools and generators, offering a flexible and reliable solution for equipment management. Integrating barcode technology with GPS tracking enhances inventory management of smaller non-powered tools, improving traceability and ensuring all assets are accounted for.

Combining these tracking devices and technologies provides a comprehensive approach to managing both powered and non-powered assets. From ensuring compliance and operational efficiency to minimizing rental costs and enhancing inventory management, a GPS tool tracker offers invaluable benefits for businesses relying heavily on their equipment.

4 Use-Cases for GPS Equipment Tracking

1. As a Geofence

A geofence is a virtual boundary that leverages GPS signals to establish an invisible perimeter. When a device equipped with an equipment GPS tracker crosses this predefined boundary, companies receive an alert or notification. This system is instrumental in preventing theft and misuse. In the event of a theft, businesses and law enforcement can quickly and efficiently locate the stolen equipment using the tool tracker.

2. To Improve Safety

Using telematics in conjunction with GPS tracking for equipment enables companies to gain detailed insights into vehicle usage. Telematics can monitor a vehicle’s speed, braking incidents, and driver handling of turns. The appropriate telematics software can assess risk factors based on a driver’s road behavior and recommend safety improvements. Companies can utilize this data to educate their staff and provide additional training to mitigate risky driving behaviors.

3. To Optimize Your Maintenance Strategy

GPS for construction equipment offers more than just location tracking. With the right tracker-software combination, companies can monitor runtimes, distances traveled, upcoming maintenance schedules, and more. Data collected from the equipment tracker can help determine the appropriate maintenance intervals for each asset based on runtime or distance traveled, ensuring optimal equipment condition. Depending on the software provider, companies can also schedule appointments and assign maintenance tasks to specific employees within the maintenance software or app.

4. For Remote Site Management

If work order management is part of the tracking software, companies can manage construction sites and other workplaces remotely. Employees can issue work orders directly related to the asset and receive updates on the completion of specific tasks. GPS tool trackers are also instrumental in deploying machines, coordinating workers, and overseeing maintenance tasks, making them an essential tool for efficient site management.

The 3 Best GPS Trackers for Tools and Equipment

ToolSense Rocbird

ToolSense offers a comprehensive equipment management solution that includes equipment tracking, maintenance management, inventory management, and work order management. It works with various IoT solutions, such as GPS trackers, Bluetooth sensors, and unique QR codes, so that businesses gain maximum flexibility by combining tracking methods that suit the individual assets best.

ToolSense’s tracker “Rocbird” is a small GPS device that can be easily attached to machines, containers, tools, and more, without becoming obtrusive or getting in the way of important tasks. It offers reliable GPS location tracking around the world. The IP68 rating makes it suitable for a variety of outdoor equipment, such as construction equipment, because it is protected against water, mud, and dust.

The cloud-based software solution and mobile app allow employees to issue and receive work orders, access maintenance schedules and checklists, as well as other file types that can be stored in the asset’s lifecycle folder. ToolSense becomes a single source of truth for information related to your equipment, sends out customizable reminders, and offers helpful insights and analytics to further optimize asset utilization and maintenance strategies. It can be used for any type of equipment and offers a free trial.

Qtanium 400

A good choice for hefty equipment is the GPS equipment tracker and accompanying software Qtanium 400. Due to its IP64 rating and geofencing abilities, it is perfectly suited for construction equipment and other types of vehicles that are exposed to rain and mud. Additionally, it offers insightful reporting and enables companies to schedule and manage maintenance appointments within the software.

TS10: Plant Machinery GPS Tracker

For businesses operating on a tight budget, the TS10 Plant Machinery GPS tracker is a more affordable alternative. It is waterproof, easily installed, and unobtrusive. Real-time tracking and geofencing alerts that are sent straight to your phone offer excellent theft protection. Additionally, the TS01 Plant Machinery GPS tracker grants access to the vehicle’s full movement history for analytics and planning purposes.

Comparison Table

The following table showcases the three introduced GPS devices and compares certain key features.

| ToolSense Rocbird | Qtanium 400 | TS10 Plant Machinery GPS tracker | |

| Suitability | For all types of equipment | Most suitable for heavy equipment | Most suitable for heavy equipment |

| Waterproof Rating | IP68 | IP67 | IP67 |

| Geofencing | ✅ | ✅ | ✅ |

| Phone Alerts | ✅ | ✅ | ✅ |

| Insights | Extensive insights | Extensive insights | Only vehicle history |

| Maintenance Management | ✅ | ✅ | ⛔️ |

| Work Order Management | ✅ | ⛔️ | ⛔️ |

| Free Trial Available | ✅, learn more | ⛔️ | ⛔️ |

Conclusion

Tracking your equipment brings many benefits: theft protection, better maintenance management, improved safety, and increased profits. Utilizing GPS equipment tracking, which picks up signals emitted by satellites orbiting our Earth, is one of the easiest and most reliable ways to locate and track assets successfully. It constitutes the basis for comprehensive asset management and better asset utilization.

ToolSense offers an all-in-one, easy to use software solution that is suitable for all types of businesses and industries and compatible not just with GPS equipment trackers, but also with Bluetooth sensors, RFID chips, and QR codes. This allows businesses maximum flexibility while also offering other must-have features, such as remote access via an app, clever lifecycle folders, and insightful analytics. By combining asset tracking, asset management, maintenance management, inventory management, and work order management in a single platform, companies receive everything they will ever need to manage their daily workflows and assets without having to invest in multiple expensive solutions.

FAQ: The Best GPS Tracker for Equipment and Tools

An equipment tracking system effectively prevents equipment theft by offering real-time location tracking and instant alerts for unauthorized movements, enabling swift intervention to protect assets.

There are several types of GPS equipment tracking tailored for different equipment, including heavy machinery, vehicles, and battery-powered options for smaller tools. Selecting the appropriate equipment tracker ensures optimal tracking and management of your assets.

Geofencing in GPS tracking systems enables users to create virtual boundaries and receive notifications when tracked assets breach these areas, thereby improving security and operational management.

GPS tool trackers offer precise location updates, route optimization, geofencing, historical data analysis, speed monitoring, and maintenance reminders, ensuring effective asset management and tracking.

Yes, a battery-powered GPS tracking device is effective for non-powered assets such as tools and generators, ensuring reliable and long-lasting location tracking.

ToolSense is trusted by 700+ companies